Model Engine Plans and Kits

Model engine plans and kits at LittleMachineShop.com. A full range of tools and accessories for the home shop machinist, including everything for your mini lathe and mini mill. |

3137 British Toy Loco Material Kit

- Working British toy loco steam engine

- Includes virtually all the material and drawings you need to make this engine

- You machine the parts

- CAD drawings and complete construction manual

This is an operating toy steam engine.

This kit includes 65 pages of drawings and 60 pages of construction notes that are specific to the mini mill and mini lathe.

When finished, the British toy loco measures 2.23" wide x 6.43" long x 3.72" high. If runs on 027 gage track which is 1.25" between the rails.

Because of the difficulties and dangers of using steam, these engines are most often powered by compressed air. |

|

2515 Buffalo Pup Steam Tug Boat Plans

- Radio controlled 36" model tug boat runs on live steam

- Build the 2 cylinder steam engine from bar stock

- Build the copper boiler

- Build the boat, including propeller and rudder

- Install the radio control

Complete plans to build a steam driven, radio controlled model of a tug boat.

These plans were created by Bill Reichart.

There are 30 pages of plans that cover building the boat including, building the boiler out of copper, and building the steam engine out of bar stock, and building the deck and cabin out of wood. The hull is fiberglass.

Sources are provided for all purchased parts including propane, the ceramic burner, and the fiberglass hull. |

|

1133 Cutting Tools for Oscillating Engine Kit

- All the cutting tools for the Oscillating Engine Kit

- Includes Drills, Taps and Dies

- Teachers: Get one of these for every 2 or 3 machines.

All of the taps, dies and drills necessary to build the Oscillating Steam Engine Kit (part number 2594).

See the contents tab for the complete list of tooling in this kit. |

|

2342 Elbow Engine Plans

Complete plans to build a unique 5-cyliner steam engine.

These plans were created by Bill Reichart.

This steam engine has 10 pistons and no crankshaft. The plans include six pages of detailed drawings and construction notes. The engine is made from bar stock. No castings are required. |

|

2340 Epicyclic Steam Engine Plans

Complete plans to build an epicyclic steam engine.

These plans were created by Bill Reichart.

This engine uses a unique set of epicyclic gears where one gear revolves around another gear. There are 33 pages of plans that detail every part and describe methods of production. The engine is made from bar stock. No castings are required. You get the gears from Boston Gear. |

|

2758 Flywheel, 4-1/2" Diameter, 6 Curved Spokes

- Cast iron flywheel

- Highest quality made by Martin Model & Pattern

- Fully Annealed

The flywheel casting is oversize so you can finish it to the specified diameter. This flywheel has a rim width of 0.875", a rim thickness of 0.291", a hub diameter of 0.794", and an overall hub length of 1.281". |

|

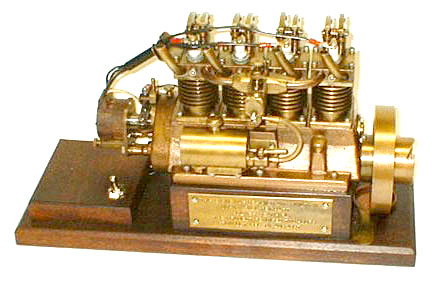

3135 Model Steam Launch Engine Material Kit

- Working model of a steam launch boat engine

- Includes all the material and drawings you need to make this model

- You machine the parts

- CAD drawings and complete construction manual

This is a working model engine kit.

This Elderberry Steam Engine kit includes 15 pages of drawings and 32 pages of construction notes that are specific to the mini mill and mini lathe.

When finished, the launch engine measures 2.00" wide x 2.93" long x 3.17" high.

Because of the difficulties and dangers of using steam, these engines are most often powered by compressed air. |

|

3136 Model Steam Mill Engine Material Kit

- Working model of a steam mill engine

- Includes all the material and drawings you need to make this model

- You machine the parts

- CAD drawings and complete construction manual

This is a working model engine kit.

This model steam engine kit includes 35 pages of drawings and 32 pages of construction notes that are specific to the mini mill and mini lathe.

When finished, the mill engine measures 2.79" wide x 4.54" long x 3.08" high.

Because of the difficulties and dangers of using steam, these engines are most often powered by compressed air. |

|

2594 Oscillating Steam Engine Material Kit

- Includes all the materials you need

- Plus all the hardware to assemble the engine

- Complete plans are included

- Great first project for beginners

This kit includes all the materials and hardware required to make the oscillating steam engine.

This engine can be built with a small lathe (Sherline or larger) and a drill press. A small mill (Sherline or larger) makes it easier.

You will need a source of compressed air, such as an air compressor, to run this engine. |

|

3485 Oscillating Steam Engine Material Kit and Instructional DVD

- Includes all the materials you need

- Plus all the hardware to assemble the engine

- Complete plans are included

- Great first project for beginners

- Includes Swarfrat Building the Oscillating Cylinder Steam/Air Engine DVD

This kit includes all the materials and hardware required to make the oscillating steam engine.

This engine can be built with a small lathe (Sherline or larger) and a drill press. A small mill (Sherline or larger) makes it easier.

You will need a source of compressed air, such as an air compressor, to run this engine.

Our Oscillating Steam Engine kit is suitable for almost any level of machinist to build. The simple design of the engine makes it function on basically three moving parts! On this video, SwarfRat builds the engine on-camera.

The engine is rather homely in its stock state, but SwarfRat shows you how -- with just an hour or so of extra work -- to transform it from an 'ugly duckling' into a 'swan'!

Best of all, the principle of the oscillating cylinder can be put into use for much more complicated projects. SwarfRat took the basic kit and a few inches of aluminum stock to make another simple cylinder and piston, ending up with a variable-angle twin cylinder engine.

You could easily make multi-cylinder engines in boxxer, V-twin or radial format using this principle, and they'd be buildable with only basic machinist skills. This is truly a learning experience.

The DVD includes (on disk, not printed) a complete set of drawings for the engine, a materials list, and instructions. |

|

2355 Panther Pup Engine Castings, Aluminum

These are the four castings required to make the Panther Pup engine (PN 2341).

These castings are aluminum. |

|

2341 Panther Pup Engine Plans

Complete plans to build a 4-cylinder, 4-cycle gasoline engine.

These plans were created by Bill Reichart.

The Panther Pup is an air-cooled internal combustion engine. There are 54 pages of plans, bound in a saddle-stitched booklet. The plans include detailed drawings of each part along with complete construction notes.

Two castings are required. Plans are included to make your own patterns, or castings can be purchased from LittleMachineShop.com. |

|

2343 Pip-Squeak Engine Plans

Complete plans to build a simple steam engine.

These steam engine project plans were created by Bill Reichart.

The Pip-Squeak was designed to be a very first, easy to build engine. It is built from bar stock. No castings are required. It can be made on a small hobby lathe and a small drill press. A small milling machine helps, but isn't necessary. |

|

6342 Plans, P&H 1015 Crane Model - 1/12th Scale

- Complete plans to build a model P&H Model 1015 crawler crane

- Crane can be configured with boom length over 9 feet

- USB Flash Drive containing 7 GB including complete plans and annotated construction photos

This Crane Model is a 1/12th scale, fully functioning 8-channel Radio Controlled replica of the 1960s vintage P&H Model 1015 (110-ton capacity) Lattice Boom Crawler Mounted Crane. Power for the model is provided by a 12 Volt, 22 Amp Hour LiFePO4 battery that is mounted at the right rear of the cab. The model’s left and right crawler treads are powered independently with 12 Volt gearmotors and propel the model at a scale speed of 60 inches per minute. The single Boom Hoist Drum, two Cable Hoist Drums and the Cab Swing are each powered by modified 12 V windshield wiper (worm gear) motors from late model VWs. The lattice boom is a hybrid design that utilizes select straight 5/16” diameter oak x 36” long corner rods with 1/8” diameter poplar lattice members, however the boom areas of stress concentration including the Boom Tip section, Boom End sections and the Boom Base section are 50/50 soldered brass tubing fabrications.

While a lot of time was spent in the design and documentation of over 117 two-view engineered drawings for all of the components, (with many of the sketches augmented with step-by-step Word instructions) I would estimate the time required for an average hobby machinist to fabricate the model from the Crane model 1015 DIY Flash Drive plans to be around 1,200 to 1500 hours. Note that access to, and knowledge of both a metal lathe (7” Swing Over Bed x 16” Distance Between Centers min) and mill (15” x 7.5” table travel min) are required.

The Crane Model 1015 DIY Flash Drive stores over 7 GB of digital information including, 117 PDF Sketches and Instructions, over 2,600 construction photos cataloged in 53 folders for easy reference, a 21-page Excel Bill of Materials that lists the part numbers, the sketch numbers and required materials/hardware, electrical wiring diagrams, radio programing instructions, full size crane photos/brochures and a 66-page Owner’s Manual. |

|

2295 Stirling-Steele Engine Plans

- Complete plans to build a Stirling engine

- Engine is 10" tall when completed

- 26 Pages of plans

Complete plans to build a four-cylinder Stirling cycle engine from bar stock and commercial components.

These plans were created by Ronald J. Steele.

The package contains 26 pages of highly detailed drawings and instructions providing all the necessary information to produce this modern compact version of a Stirling engine. The Stirling-Steele engine can be machined on a 6" lathe and small milling machine from readily available material. A full bill of materials is included as are assembly instructions. This is not a kit but a full set of dimensioned drawings. |

|

5370 Tenderizing Hammer Material Kit

- Includes the material you need

- Complete plans are included

- Great for getting started on the lathe and the mill

The handle is all done on the lathe. It requires turning, tapering, threading, knurling and ball turning (optional).

The head is all done on the mill. It requires surfacing, drilling and tapping, corner rounding, and V-grooving. |

|