What's the Difference?

You might wonder what the difference is between the SIEG

Mini Lathe and the HiTorque Mini Lathe or between the SIEG Mini Mill and the

HiTorque Mini Mill. They share many of the same features. For example, both mini

mills incorporate the large X-Y table. (Visit our

mini mill or

mini lathe comparison

pages for more details.) The most significant difference is the

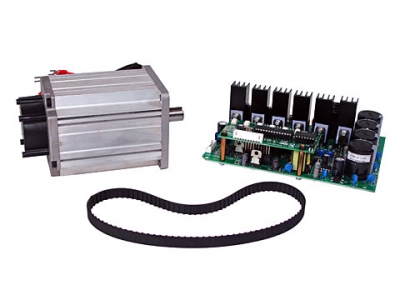

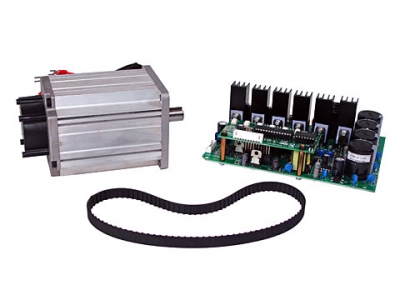

drive system. The photos below show the major components of the two drives.

SIEG Drive System |

HiTorque Drive System |

|

|

|

The SIEG drive on the mini lathe and mini mill incorporates a 350 Watt

conventional wound rotor DC motor and PWM controller card. The gears provide two

speed ranges to enhance low speed torque because the output torque of a DC drive

like this falls off as the motor speed is reduced.

|

The HiTorque drive system on the mini lathe and mini mill incorporates a 500

Watt brushless DC motor and controller. The wound stator and permanent magnet

rotor provide virtually constant torque over the entire speed range. RPM feedback

from the motor to the controller helps insure constant speed through varying

loads.

|

|

See the SIEG machines

|

See the HiTorque Machines

|

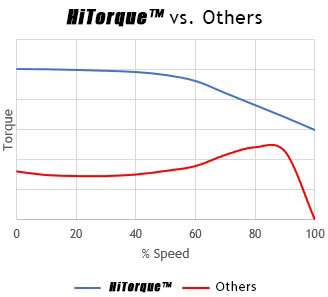

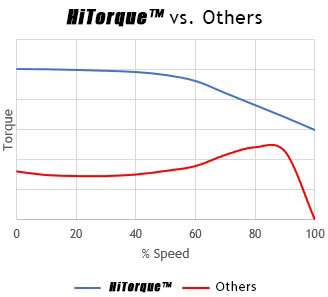

Why Is the HiTorque Drive Better?

Besides simply having more horsepower (500W is

0.67hp, 350W is 0.47hp), the brushless DC drive in the HiTorque mini lathe and

mini mill have greater torque, especially at low speeds. Compare the typical

torque curves. Besides simply having more horsepower (500W is

0.67hp, 350W is 0.47hp), the brushless DC drive in the HiTorque mini lathe and

mini mill have greater torque, especially at low speeds. Compare the typical

torque curves.

The HiTorque drive lets you take deeper cuts at all

speeds, and the low speed torque makes slow-speed operations like parting off

significantly easier.

Because of the nearly linear torque curve, the HiTorque drive does

not need 2-speed gears. There is one continuous speed range. This means there

are no gears to shift and no plastic gears to break.

|

YouTube Videos

These videos provide more information than most of us want to know.

|

| About PWM |

About brushless DC motors |

|

Besides simply having more horsepower (500W is

0.67hp, 350W is 0.47hp), the brushless DC drive in the HiTorque mini lathe and

mini mill have greater torque, especially at low speeds. Compare the typical

torque curves.

Besides simply having more horsepower (500W is

0.67hp, 350W is 0.47hp), the brushless DC drive in the HiTorque mini lathe and

mini mill have greater torque, especially at low speeds. Compare the typical

torque curves.

Chip Shield, Magnetic for 3" - 4" Vise, Clear

Chip Shield, Magnetic for 3" - 4" Vise, Clear